Common Hydraulic Repair Parts: What You Need to Know

Hydraulic systems are critical in many types of heavy machinery, including excavators, loaders, and industrial equipment. Over time, hydraulic components wear out due to high pressure, heat, contamination, and continuous use. To keep the system running efficiently and avoid costly downtime, timely repair and replacement of parts is essential.

Here’s a breakdown of the most common hydraulic repair parts used in maintenance and repair operations.

1. Hydraulic Seals and O-Rings

Hydraulic seals are among the most frequently replaced parts. They prevent fluid leaks and maintain pressure within the system.

- O-Rings

- Rod seals

- Piston seals

- Wiper seals

- Backup rings

These seals come in various materials (like NBR, Viton, or polyurethane) depending on operating temperature, pressure, and fluid compatibility.

2. Hydraulic Hoses and Fittings

Flexible hydraulic hoses carry fluid between components. Over time, they can crack, leak, or burst.

- High-pressure hoses

- Return hoses

- Quick couplings

- Threaded fittings

- Adapters and connectors

Always replace with hoses rated for the correct pressure and temperature range.

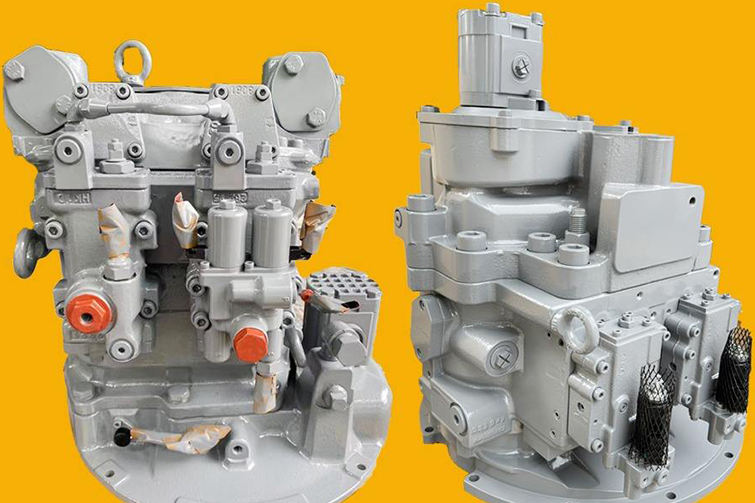

3. Hydraulic Pumps and Motors

If your hydraulic system loses power or operates slowly, a failing pump or motor may be the cause.

- Gear pumps

- Piston pumps

- Vane pumps

- Hydraulic motors (fixed or variable displacement)

These are complex components and may require complete replacement or internal part repair (bearings, shafts, valves).

4. Control Valves and Valve Components

Control valves direct the flow of hydraulic fluid. When they malfunction, they can cause sluggish movement or complete system failure.

- Directional control valves

- Pressure relief valves

- Flow control valves

- Solenoids and spools

- Valve seals and springs

Repairing valves often involves replacing internal seals, springs, or coils.

5. Hydraulic Cylinders and Cylinder Parts

Hydraulic cylinders convert fluid power into mechanical movement. When they leak or lose power, it may be time for a repair.

- Cylinder seals and kits

- Pistons and rods

- Rod ends and bushings

- Cylinder tubes

- Gland nuts and retaining rings

Seal kits are among the most common repairs for hydraulic cylinders.

6. Filters and Fluid

Contaminated fluid is a major cause of hydraulic failure. Routine replacement of filters and fluid helps protect sensitive components.

- Return filters

- Suction filters

- Inline filters

- Hydraulic oil (ISO VG grades)

Always use the fluid recommended by the equipment manufacturer.

7. Other Important Repair Parts

- Accumulators and bladders

- Heat exchangers or oil coolers

- Pressure gauges

- Mounting brackets

- Electronic sensors (for modern systems)

Each of these plays a vital role in maintaining system performance and safety.

Final Thoughts

Understanding the key components used in hydraulic repairs can save you time, money, and machine downtime. Whether you're maintaining a construction excavator or an industrial press, having access to the right hydraulic repair parts—and replacing them proactively—ensures smooth, safe, and efficient operation. Always use high-quality parts and follow manufacturer recommendations for maintenance and replacement intervals.