How to Choose the Right Hydraulic Pump for an Excavator

The hydraulic pump is the heart of an excavator’s hydraulic system—it delivers the power needed to operate the boom, arm, bucket, and other hydraulic functions. Choosing the right hydraulic pump is critical for ensuring efficiency, performance, and longevity of your machine. Whether you're replacing a worn-out pump or upgrading to a higher-performance model, here are the key factors to consider when selecting a hydraulic pump for an excavator.

1. Know Your Machine Specifications

Before choosing a hydraulic pump, you need to understand the exact specifications of your excavator:

- Make and model of the machine

- Engine horsepower

- Operating weight

- Hydraulic flow and pressure requirements

- OEM (Original Equipment Manufacturer) part number

Always refer to your machine’s manual or contact the manufacturer to ensure compatibility.

2. OEM vs. Aftermarket

- OEM Pumps: Original Equipment Manufacturer pumps are designed specifically for your excavator model. They guarantee compatibility and usually come with a warranty.

- Aftermarket Pumps: These can be more affordable, but quality varies. Make sure to buy from a trusted supplier that meets or exceeds OEM specifications.

If budget allows, OEM pumps are generally more reliable, but high-quality aftermarket options can also be a good choice for older machines or cost-sensitive projects.

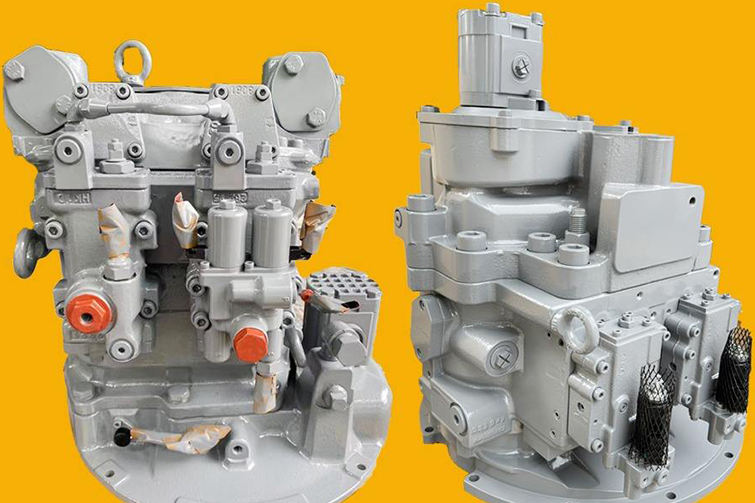

3. Pump Type

Excavators typically use different types of hydraulic pumps. Common ones include:

- Piston Pumps: Most common in excavators, known for high pressure and durability.

- Gear Pumps: Simpler and more affordable, but generally less efficient and used in smaller equipment.

- Vane Pumps: Quiet and efficient, but not as common in heavy-duty applications.

For medium to large excavators, axial piston pumps are the standard due to their performance and reliability under high load.

4. Performance Ratings

Check the technical ratings of the pump:

- Flow Rate (L/min or GPM): Should match the system’s hydraulic demand.

- Operating Pressure (bar or PSI): Must meet or exceed the working pressure of your system.

- Speed (RPM): Ensure the pump can operate efficiently at the engine’s RPM range.

Mismatched specs can lead to overheating, poor performance, or even damage.

5. Quality and Brand Reputation

Always choose pumps from reputable brands or manufacturers with a proven track record in heavy machinery parts. Look for:

- Quality certifications (e.g., ISO)

- Positive reviews or customer feedback

- Warranty coverage

- Support and availability of spare parts

Trusted brands often offer better customer service and long-term reliability.

6. Installation and Maintenance Considerations

- Choose a pump that fits your machine without the need for excessive modification.

- Ensure that spare parts (seals, valves, etc.) are available.

- Understand the maintenance needs and service intervals of the pump.

Final Thoughts

Choosing the right hydraulic pump for your excavator is essential for maximizing productivity and minimizing downtime. Always consider compatibility, performance specifications, quality, and brand reputation. If you're unsure, consult a qualified technician or contact the manufacturer for guidance. The right pump will ensure smooth operation and long-term value for your investment.